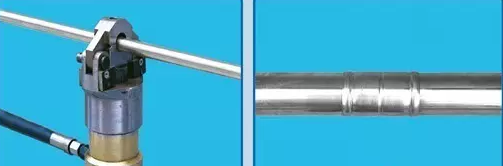

Definition of ring pressure: a connecting type in which the cylindrical wide-band sealing ring is sleeved on the pipe, inserted into the socket of the ring pressure type pipe fitting, the special tool is used to press along the peripheral direction of the socket from the outside, so that the socket and the pipe are concave and deformed together, and the sealing section of the socket is compressed, so as to achieve the fastening and sealing of the pipe fitting.

Advantages: high connection strength, good sealing performance, operating tools 'fool', easy to install.

Disadvantages: the pipeline is fixed connection and cannot be disassembled at will.

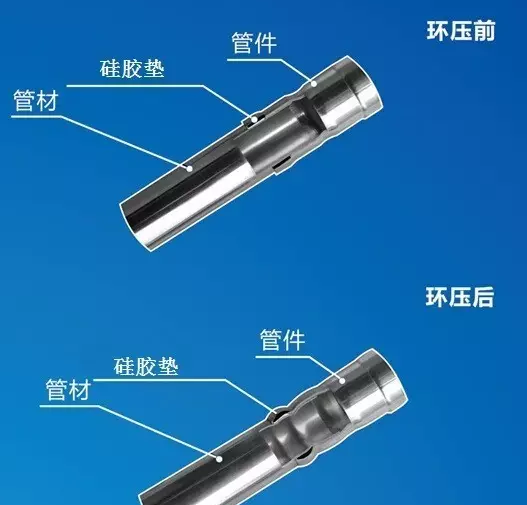

Ring pressure connection structure diagram

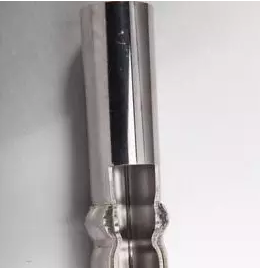

Principle as shown in the figure: the socket of the ring pressure pipe fitting is divided into the stable section and the sealing section. The port of the sealing section is open, and the port is closed only after the ring pressure. During the ring pressure connection, the cylindrical rubber sealing ring is installed on the pipe into the socket of the pipe fitting, and the hydraulic tool and the ring pressure die are used to exert enough radial pressure on the connection part of the pipe fitting and the pipe fitting, so as to shrink the outer diameter of the pipe fitting and insert the concave part into the pipe fitting. After the ring pressure, the connection part of the pipe fitting and the pipe fitting is as if the screw thread is engaged with each other, and at the same time, a sealed sealing cavity is formed in the sealing section of the pipe fitting, which is passed through the In one step, the volume of the sealing cavity is compressed so that the sealing material can fully fill the entire sealing cavity to achieve sealing. 'Ring compression fastening' and 'wide band sealing' are two major technical features of ring compression connection. This technology greatly reduces the dependence of pipe connection on pipe wall thickness. On the premise of ensuring more reliable connection and sealing, it is possible to further thin-walled stainless steel pipes. At present, the ring pressure technology has obtained 22 national patents.

The economic advantages of ring pressure connection technology can be summarized as follows:

1、The ring pressure connection realizes the reliable connection of cold extrusion technology in DN125 and 150 large diameter pipes, and establishes the leading position of the ring pressure technology in the same industry at home and abroad.

2、Compared with the traditional cold extrusion connection, the fastening method of ring pressure connection has substantial changes and breakthroughs.

The traditional tightening method of cold extrusion connection is to force the pipe fittings and pipes into hexagon through external force, and generate strong tightening force at six corners of hexagon through deformation, which enables the pipes to withstand the pipe fittings to realize the connection. The external shape of the pipe is not changed by the ring pressure connection, but the external diameter of the pipe is forced to shrink along the circumference direction to force the pipe to be concave and embedded in the pipe. After the ring pressure, the connection between the pipe and the pipe is like the thread mouth. At the same time, the forced contraction produces a holding force at each point of the concentric circle of the pipe to make the pipe tightly hoop the pipe.

3、The design of the sealing cavity of the ring pressure connection ensures that the leak proof performance of the system connection is more reliable.

The traditional cold extrusion connection is sealed by rubber O-ring, which has a limited sealing contact surface and a 'line' structure. Theoretically speaking, only a completely closed line is needed for the realization of sealing, but in this way, the accuracy requirements for pipe fittings and sealing rings are relatively high. At the same time, the installation process is also required to be careful. If there is a little difference, leakage will occur. And the ring pressure connection is specially designed with a section of sealing cavity, which is formed by the ring pressure of the sealing section after the cylindrical sealing material on the pipe sleeve is inserted into the pipe fitting. In the process of ring pressure, a closed sealing cavity will be formed at the sealing part first, and the sealing material will fully fill the space and gap of the cavity by compressing the volume of the cavity, and then the sealing cavity will be locked after further pressing and extruding the redundant sealing material. The ring pressure connection is a 'wide-band' seal, and the two ends of the cavity are wedge-shaped. In addition, the working face of the sealing cavity is wide, which ensures the leak proof performance of the system connection.

4、The economic effect of ring pressure connection technology is more obvious.

The economic effect of ring pressure connection is reflected in two aspects: pipe fittings and pipes. First of all, compared with other non welding connection methods, the structure and shape of the ring pressure pipe fittings are simpler. There are only two expanding steps at the head of the pipe fittings, which reduces the complicated process of making O-ring inner hoop groove by traditional cold extrusion pipe fittings. Therefore, the production accuracy requirements are not high. The mass production can be realized by adopting the regular process and general equipment, and the product yield is high. Secondly, the dependence of the ring pressure connection on the wall thickness of the pipe is lower than that of the traditional cold extrusion connection. For example, as for the stainless steel pipe of DN15, the traditional cold extrusion connection requires the wall thickness of the pipe to be 0.8 mm, and the ring pressure connection requires the wall thickness to be 0.6 mm; while the traditional cold extrusion connection in the square of the system tensile strength is > 3.0 MPa, and the ring pressure connection is > 4.5 MPa, so the ring pressure stainless steel pipe ratio The traditional cold extrusion tube is more material saving and has the economic and technical conditions for popularization.

5、The installation of ring pressure connection is more simple and reliable.

The requirements for fitting tolerance of pipe and pipe fittings in the ring pressure connection are wide. The construction personnel only need to insert the sealing ring into the pipe fittings, and then use the ring pressure tool to press. When pressing, the tool module can find its position by itself and release pressure by itself when it is in place. The whole process of operation can effectively guarantee the quality of construction, so the requirements for construction personnel are not high. In addition, the ring pressure connection also has the characteristics of non leakage rotation and secondary pressure connection repair, which plays a positive role in improving the quality and efficiency of engineering installation.